3D printers: away from the advertising boom of a few years ago, the imporesoras 3D are to stay. Although there are other technical (granulated, laminate, etc...) the principle of depositing material plastic (or other material) known as addiction, from coordinates X, Y, Z is the most popular, fast and economic. Prior 3D design and processing of the required layer file so that the resulting piece doesn't have problems of gaps and adequate material density, as well as control of the temperature of the deposited material makes these teams away from the equipment "easy to use" domestic as printer paper.

|

Structure of the printer:

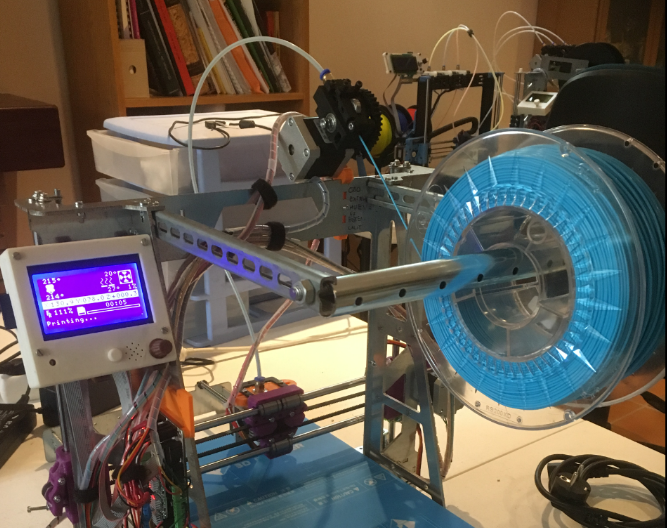

Prusa printer was that popularized the idea of "RepRap" (self-replicating manufacturing machine) that offers free software and allows you to connect users so they manufacture parts to other users, is at the same time the most easy to build and understand . Based on a minimum of 3 engines step-by-step, one for each eje(x, y, z), can with a controller card move these axes in a similar way to a plotter is done and we will be able to build any piece of layers. Using more engines for some of the axles to support the weight of the mechanical systems that extruded plastic material are the origin of many variants of this printer that are on the market. |

|

Controller card: The most popular is the arduino Mega, with its variants (Ramps, etc...) Firmware or software (Marlin, Rumba) that performs the control of the printer, is necessary to adapt it to the different configuration hardware that we can find:

|

|

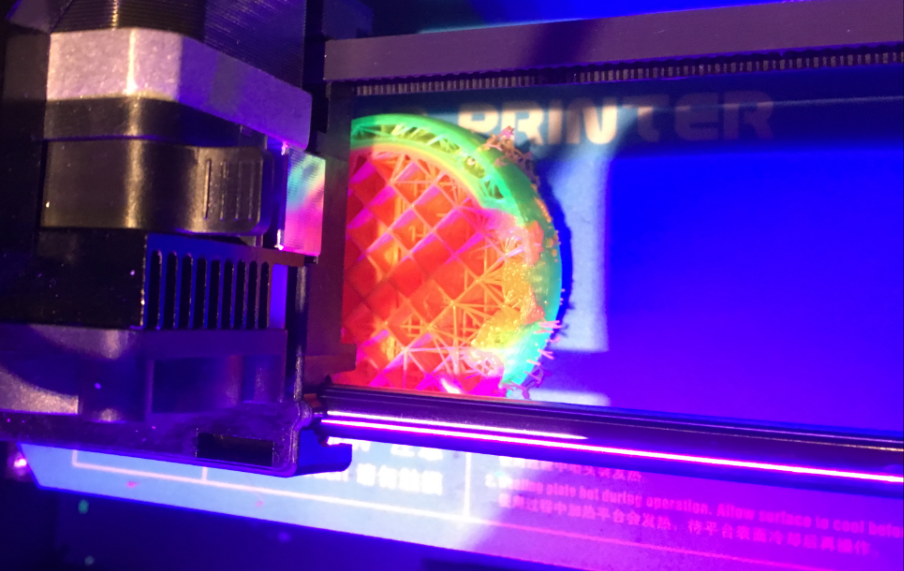

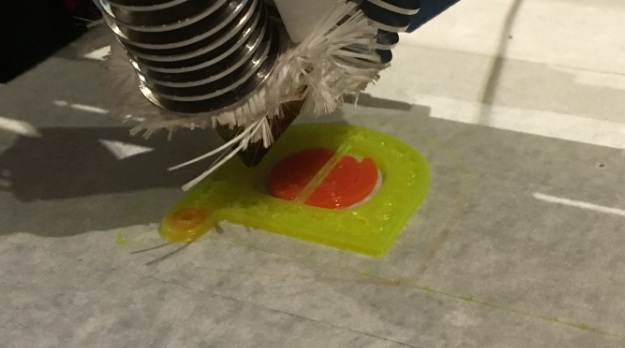

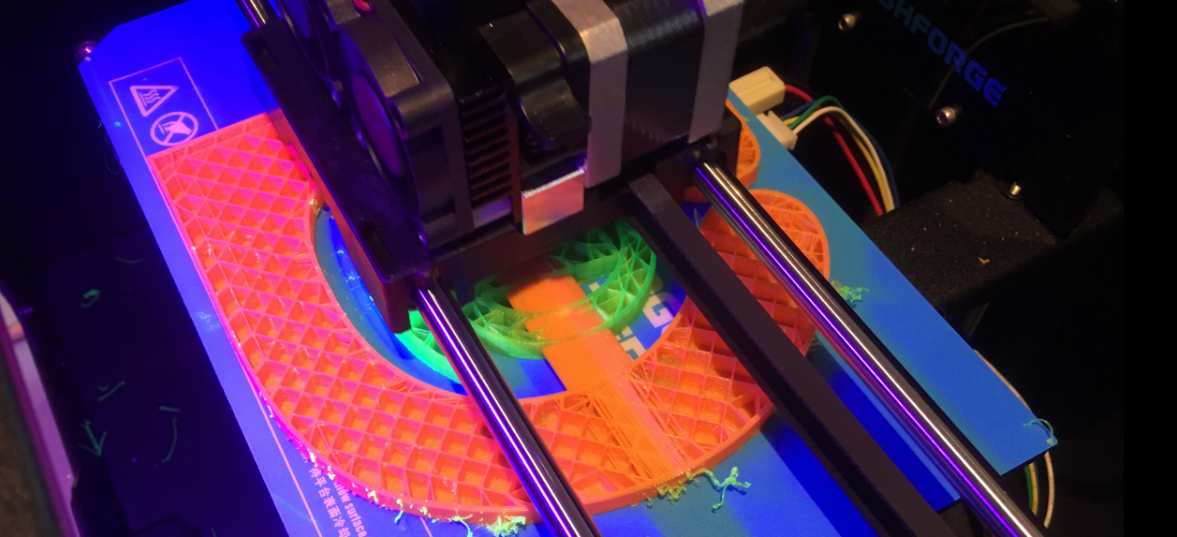

Extruder: It's the piece that heats plastic material and turns it into a hot thread < 0, 5 mm which gives us adequate precision to print any piece with this resolution. If you want to print in 2-3 colors as normal using twin-screw 2-3, there is an idea that not just working with the accuracy that an industrial system requires is the Diamond, extruder which blends 3 colors. The problem of this device is that the part that is deposited each material cannot be controlled with great precision and even more complex to find a CAD software that generates these instructions properly. Not to mention the design software that also allows to define colors of each piece |

|

3d modeling (CAD) software: Free CAD programs and online as Thinkercad are a good starting point, as progress will need to move to programs with boosting type autocad, sketchup etc... If what you want to do it has not happened before someone, should be looking at pages grabcad or thingiverse Although there are other formats the more popular to download and make it printable is an STL format file, not to mention that if you want to print in 2 colors will be 2 STL files needed (one for each color) |

|

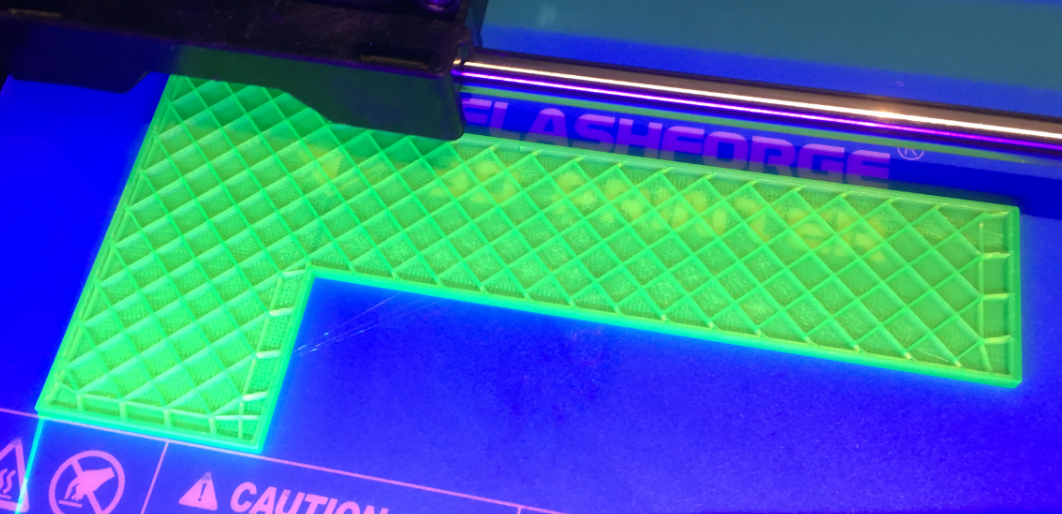

Slicing software: It normally tends to be a free software that comes with the printer you buy, but there are several known and used free software as cures, Replicator, etc.. the idea is to generate the code from the STL file that understand our 3d printer, which usually have extension .gcode and is a format type text, which we can modify for example by changing the temperature of the extruder etc on the first lines.

|

And do not forget that you can contact us for any parts you need or directly or through 3D Hubs